The Dallas Group of America’s Free Fatty Acid Test Kit

Testing for free fatty acid (FFA) in frying oil provides a clear picture of the quality of your final product. High levels of FFA directly correlate to off-colors, off-odors, and off-flavors in your fried product. With the Dallas Group of America’s (DGA) free fatty acid test kit, you can analyze the free fatty acid in your cooking oil in just 2 minutes.

The American Oil Chemists’ Society (AOCS) method 5a-40 is the standard for testing free fatty acid in cooking oils. The DGA FFA hand-held test kit was produced from the AOCS test method, but without the burets, flasks, and laboratory hardware. Its portable nature is convenient for both small and large frying operations. Testing next to the fryer or in the comfort of a laboratory setting is simple with the DGA FFA test kit.

Our FFA test kit is a convenient, accurate, and cheap way to test free fatty acid levels and can be used in all cooking oil applications. It has been proven to work, giving accurate results for cooking oil used in potato chips, corn dogs, meat browning, snack foods, breaded products, peanut roasting, and more.

Frying Oil 101

Product that is fried in high FFA oil correlates to decreased product appearance and shelf life. In a study done on potato chips, products fried in oil above 0.40% FFA saw an increase in rancidity and decreased shelf life (less than 20 days).

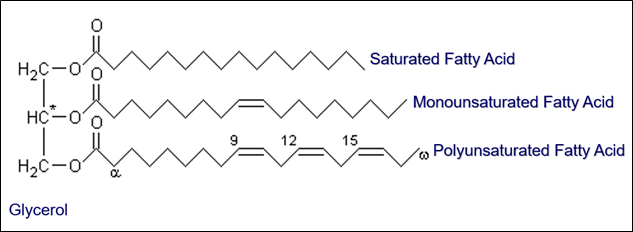

Oil is a triglyceride. During frying, the fatty acid chains are cleaved from the glycerol backbone of the triglyceride molecule. The longer the product is fried more free fatty acids are created. Oxidation, hydrolysis, and polymerization occur due to oxygen, water, and heat cleaving the FFA from the triglyceride molecule.

The results of oxidation are peroxides, aldehydes, and ketones. The results of hydrolysis are free fatty acids. The results of polymerization are dimers, trimers, and polymers. These degradation compounds have a significant effect on oil color, flavor, and odor.

Measuring FFA is vital to frying oil operations. Maintaining proper FFA levels produces a consistent-quality fried product. Within two minutes, you can have an FFA result with the DGA FFA test kit.

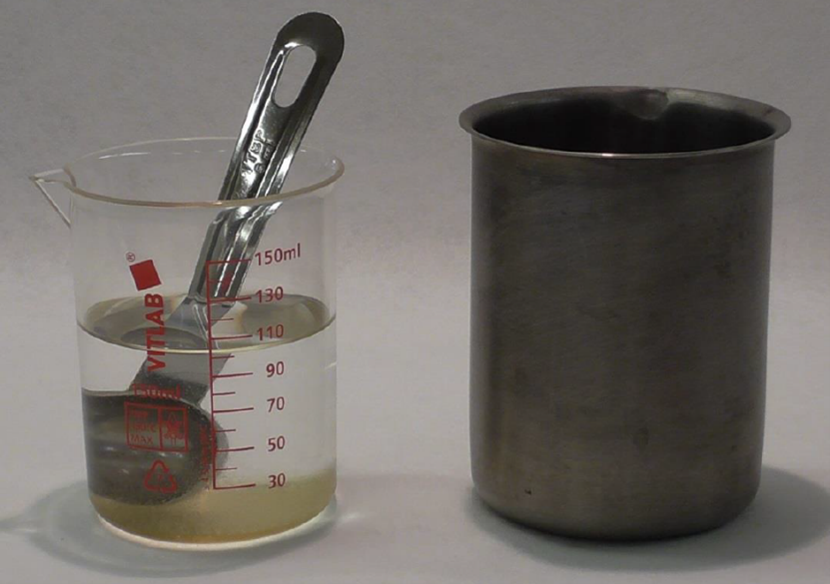

Your DGA FFA test kit includes the following:

- 150mL plastic beaker

- 30mL FFA titrant

- 30mL FFA indicator

- 5mL measuring and stirring spoon

- USB stick containing instructions

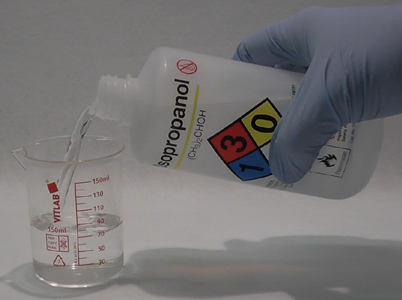

- >91% Isopropyl alcohol (rubbing alcohol)

-

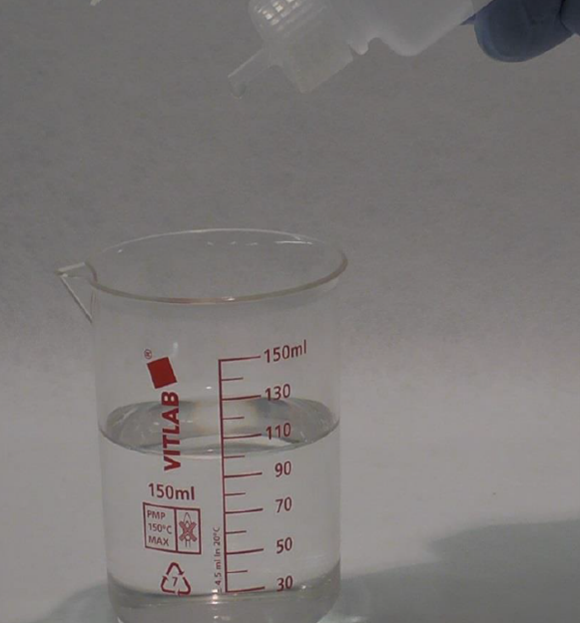

- Pour 50mL of isopropyl alcohol into the plastic beaker.

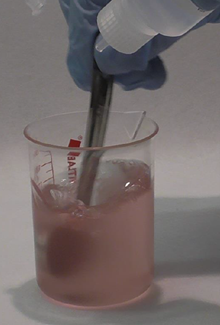

- Put 5 drops of FFA indicator into the alcohol solution in the beaker.

- Take an oil sample and use the measuring spoon to obtain 5mL. Put the 5mL oil sample into the plastic beaker and leave the measuring spoon in the beaker for stirring purposes. Stir the oil, FFA indicator, and alcohol for 5 seconds.

- Count each drop of FFA indicator as this will correlate to the final FFA reading. Put one drop of the FFA indicator in the solution at a time, counting each drop. After each drop, the solution will turn pink and back to yellow.

- Once the pink color remains and does not disappear, STOP. Stir the solution for 30 seconds. If the pink color remains after 30 seconds of stirring, record the number of drops and determine your FFA.

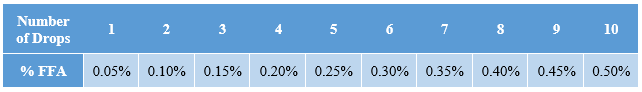

- Take the number of drops and multiply by 0.05 to obtain your % FFA results.

- Pour 50mL of isopropyl alcohol into the plastic beaker.